Research Team : Multiphysics mechanics for materials and processes

The Multimap 'Multiphysics of materials and processes' team aims to experimental analysis, modeling and simulation of the mechanical behavior of materials, . particularly during the manufacturing process.

The team studies a wide range of materials: metals, composites, polymers, ice, bio-sourced materials (wood, cellulose materials) and recycled materials. Research focuses on the multi-scale and multi-physics behavior of materials during their transformation. Their response under various thermo-(hygro)mechanical stresses (quasi-static, dynamic and rapid thermal), the behavior of continuous media (quasi-static, dynamic and rapid thermal), and the behavior of non-standard continuous media, as well as contact and friction, are analyzed.

The team's work is based on experimental and numerical studies. They involve methods for characterizing the behavior of materials (under different levels and speeds of mechanical and thermal loading); mesoscopic-scale tests to reproduce loading cycles representative of conditions encountered during the manufacturing process; devices mimicking certain manufacturing process conditions. The models proposed cover several scales, from the behavior law integrating the microstructure, to full-scale simulation of manufacturing processes.

Research focuses on three areas :

- multi-physical behavior of materials under extreme loads

- innovative manufacturing and surface treatment processes (metals and polymers)

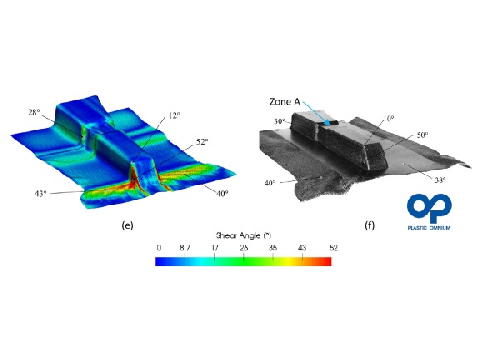

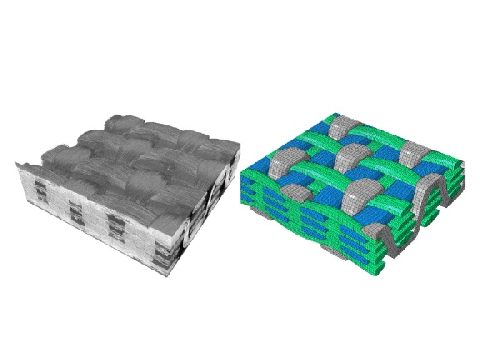

- polymer and composite shaping

Manager : Pierre DUMONT

Thematics Axis

- Experimental techniques

- Numerical aspects for dynamics

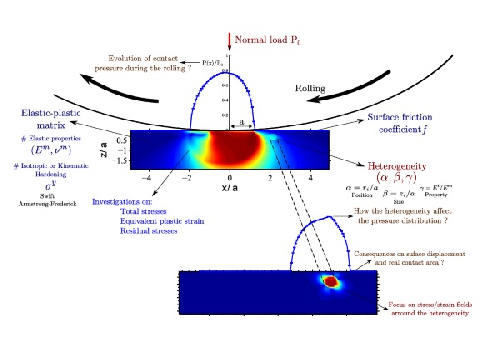

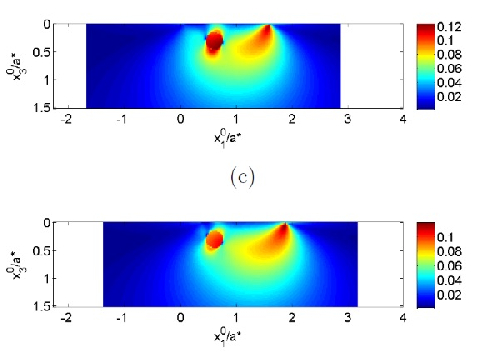

- Behavior under contact stress

- Composites forming

- Innovative manufacturing and surface treatment processes for metals and polymers

Multiphysic behaviour of materials under extreme loadings :

Composites forming :

Innovative manufacturing and surface treatment processes for metals and polymers :