- HFRR (High Frequency Reciprocating Ring)

- MTM (Mini-Traction Machine)

- EHL Ultra Thin Film

- Sensofar Neox Plu roughness tester

- Hirox Microscope

- MBDHP (High-performance dual-disc machine)

- FZG

- MBDF (Dual Fatigue Disc Machine)

Scientific manager : VILLE Fabrice

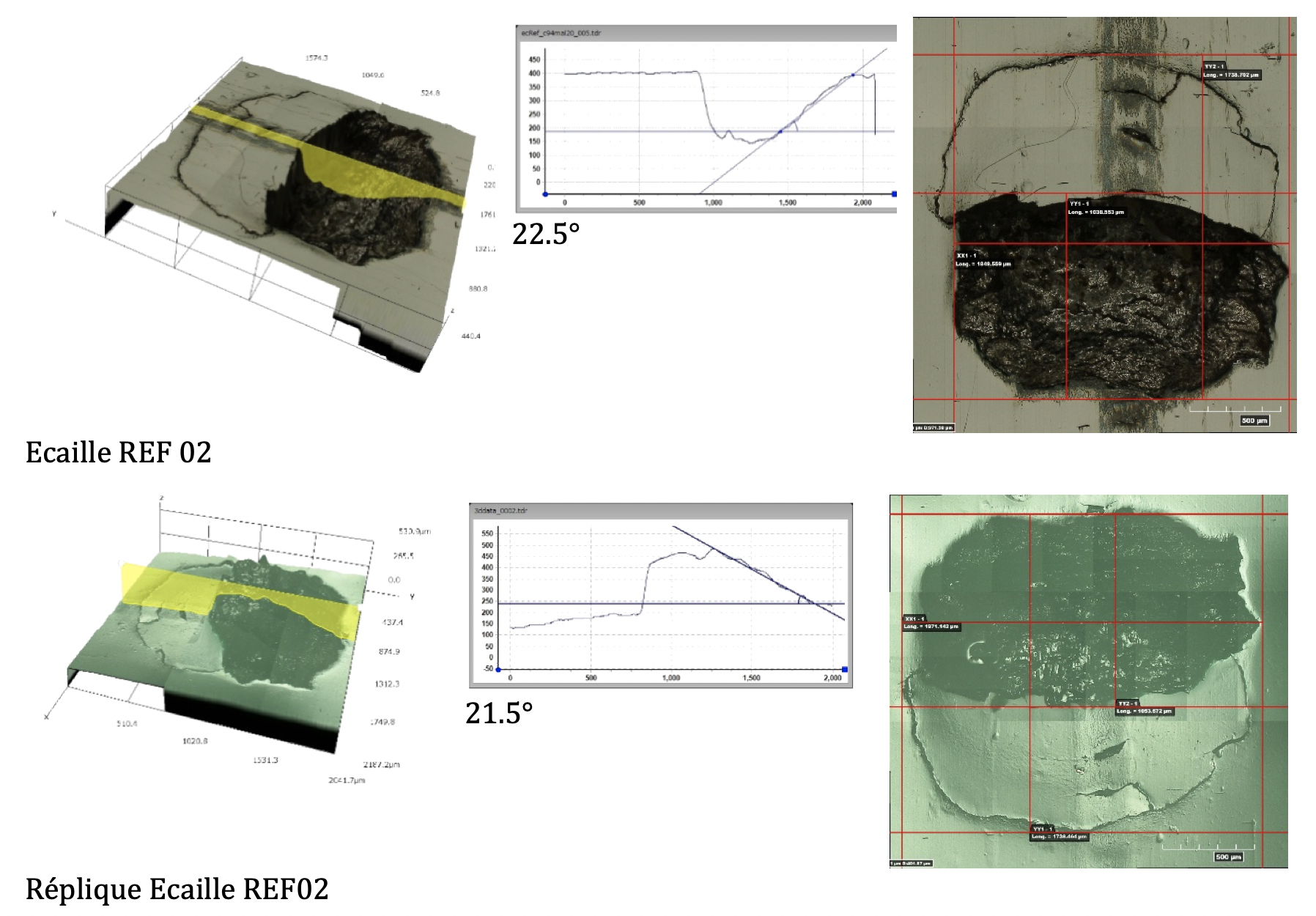

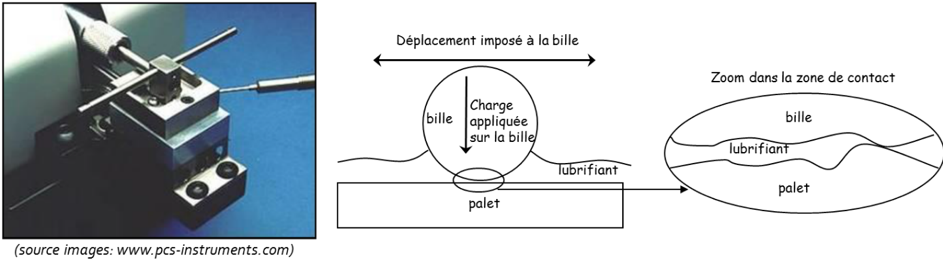

The HFRR (High Frequency Reciprocating Rig) is a test rig marketed by PCS Instruments.

It simulates pure sliding contact between a ball and a plane. The movement of the ball on the plane is rectilinear and

as shown in the diagram. The reciprocating motion is imposed by a vibrating pot.

It is used to assess the properties of lubricants, such as friction and the separation induced by the film of lubricant between the ball and the puck.

between the ball and the puck.

Puck and disc wear can also be assessed retrospectively using appropriate measurement techniques.

Microscope observations

Scientific manager : VILLE Fabrice

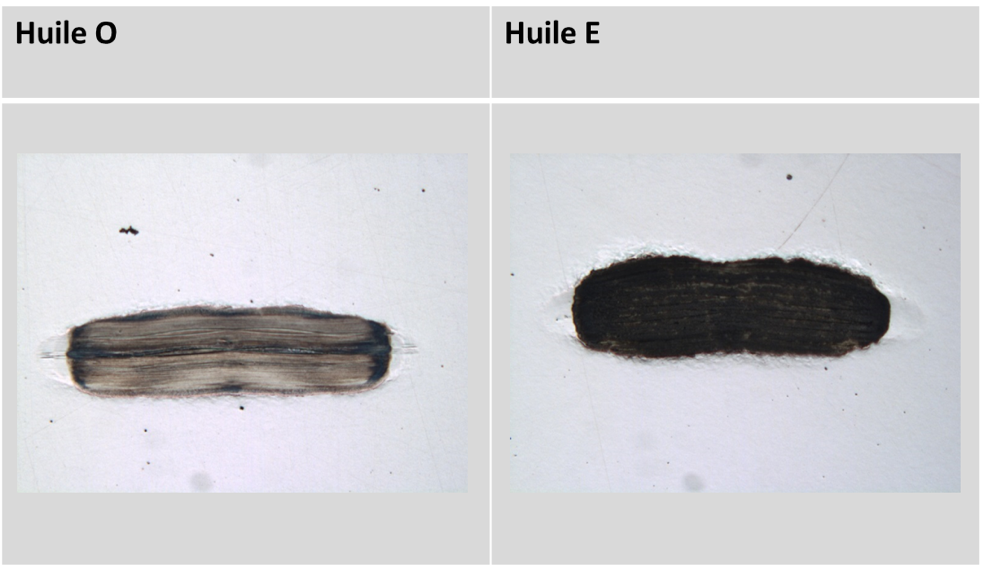

La MTM (Mini-Traction Machine) is a test bench marketed by PCS Instruments.

It is used to measure the coefficient of friction in rolling/sliding contact between a ball

(or barrel) and a disc, under a given load. The lubricant tested can be heated up to 150°C.

This machine can be used to evaluate friction as a function of the rate of sliding in the contact

(so-called 'traction' curves), the rolling speed in the contact (so-called 'Stribeck' curves) or as a

function of time (so-called 'iso-condition' curves).

Ball (or barrel) and disc wear can also be assessed retrospectively using appropriate

appropriate measurement techniques

Observations of interferometric readings :

Scientific manager : VILLE Fabrice

The Ultra Thin Film EHL machine is a test bench marketed by PCS Instruments.

It is used to measure variations in film thickness and the coefficient of friction of a lubricant in the

elastohydrodynamic regime.

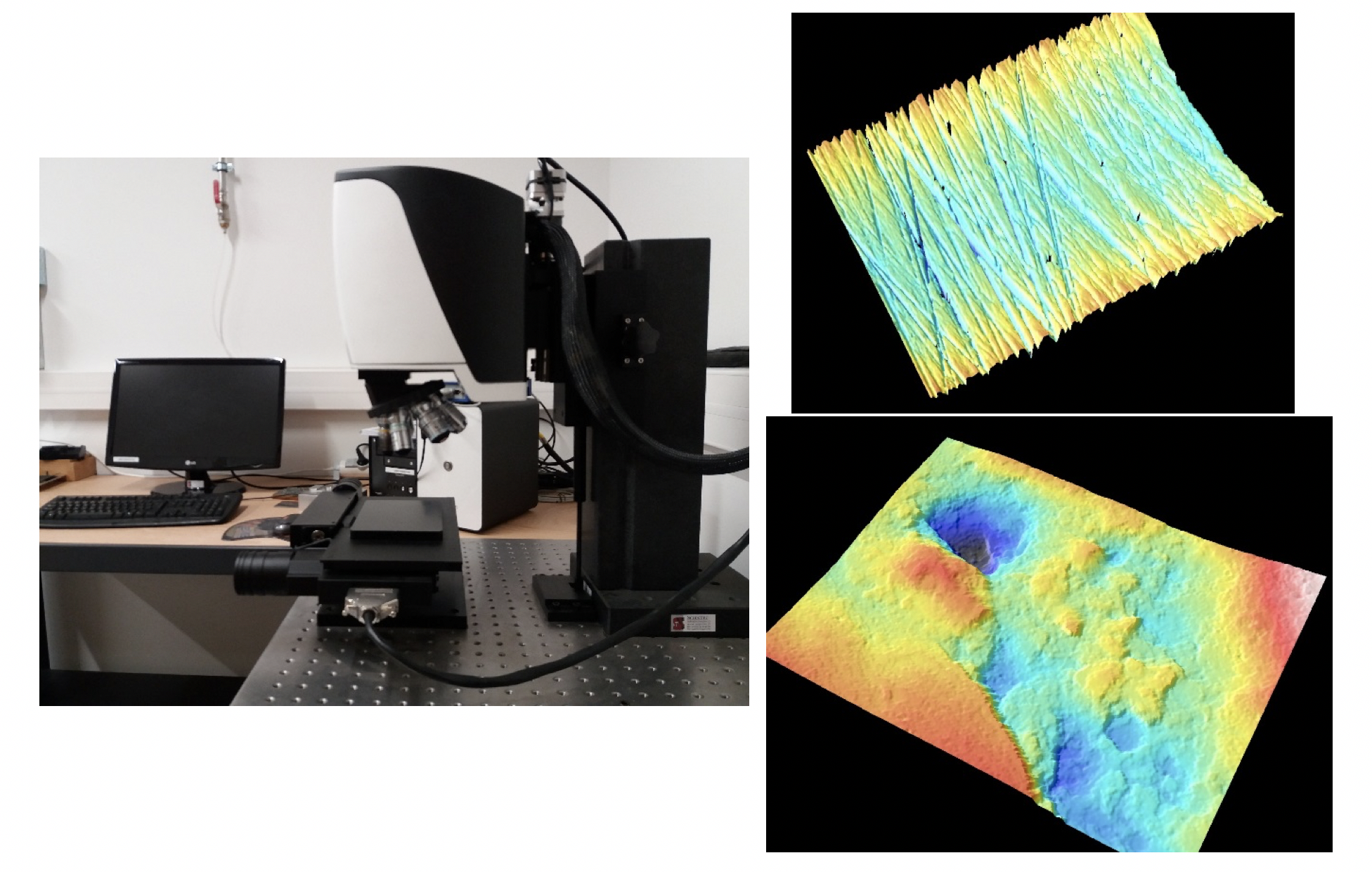

Scientific manager : VILLE Fabrice

Scientific manager : VILLE Fabrice

Scientific manager : VILLE Fabrice

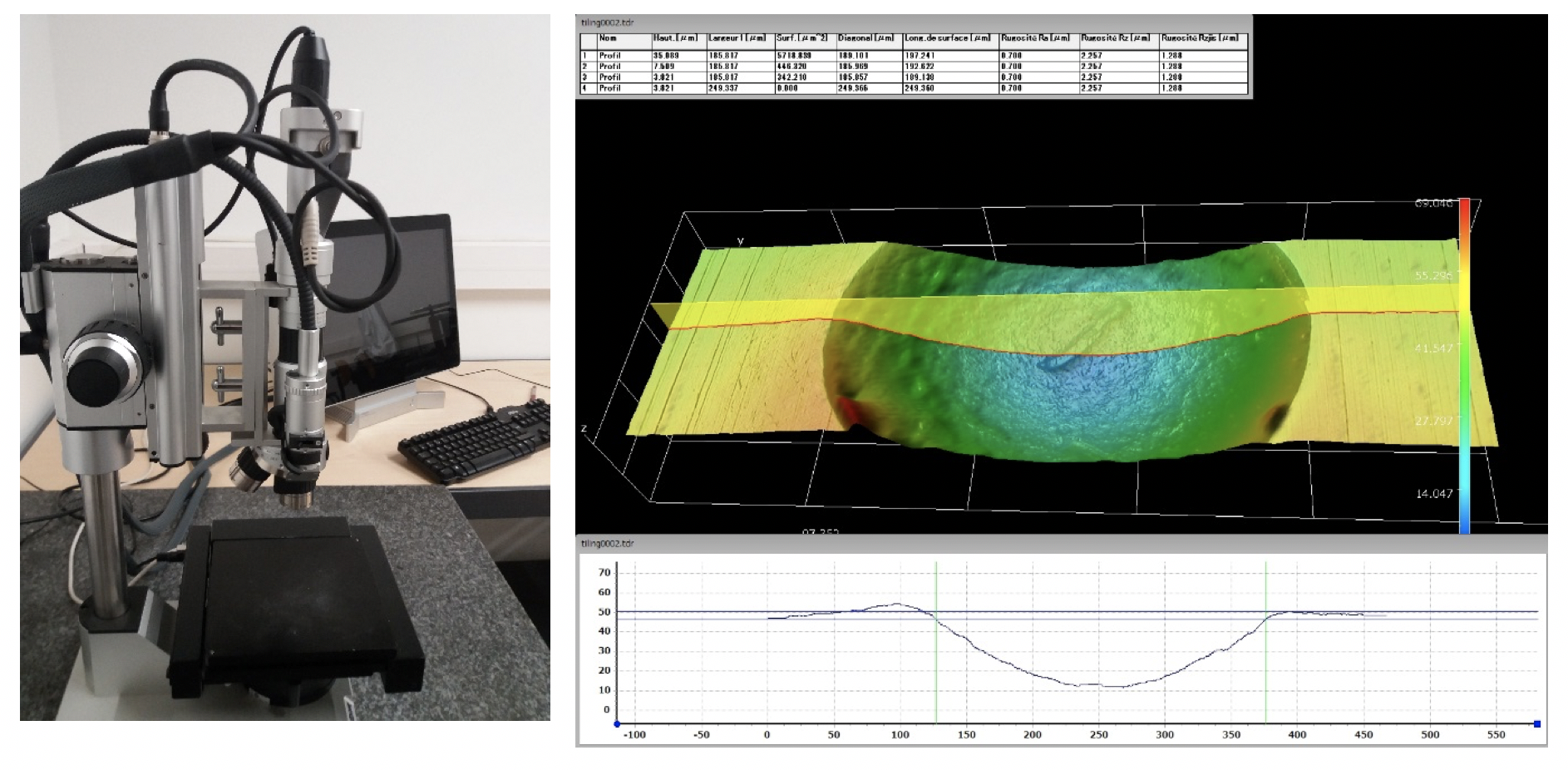

This machine can be used to simulate all types of ElastoHydroDynamic contact, such as contact between gear teeth, rolling body-ring contact in roller bearings, etc.

gear teeth, rolling body-ring contact in roller bearings, etc.

It is mainly used to produce friction curves which characterise the coefficient of friction for a

for a material-lubricant pair, under different contact conditions, or to define seizure conditions.

seizure conditions.

Thermocouples can be installed to analyse the thermal behaviour of the machine and the test

specimens being tested.

The surfaces or metallographic sections of the specimens can be analysed before and after testing

with suitable equipment (microscopy, 3D roughness measurement, etc.).

Scientific manager : VILLE Fabrice

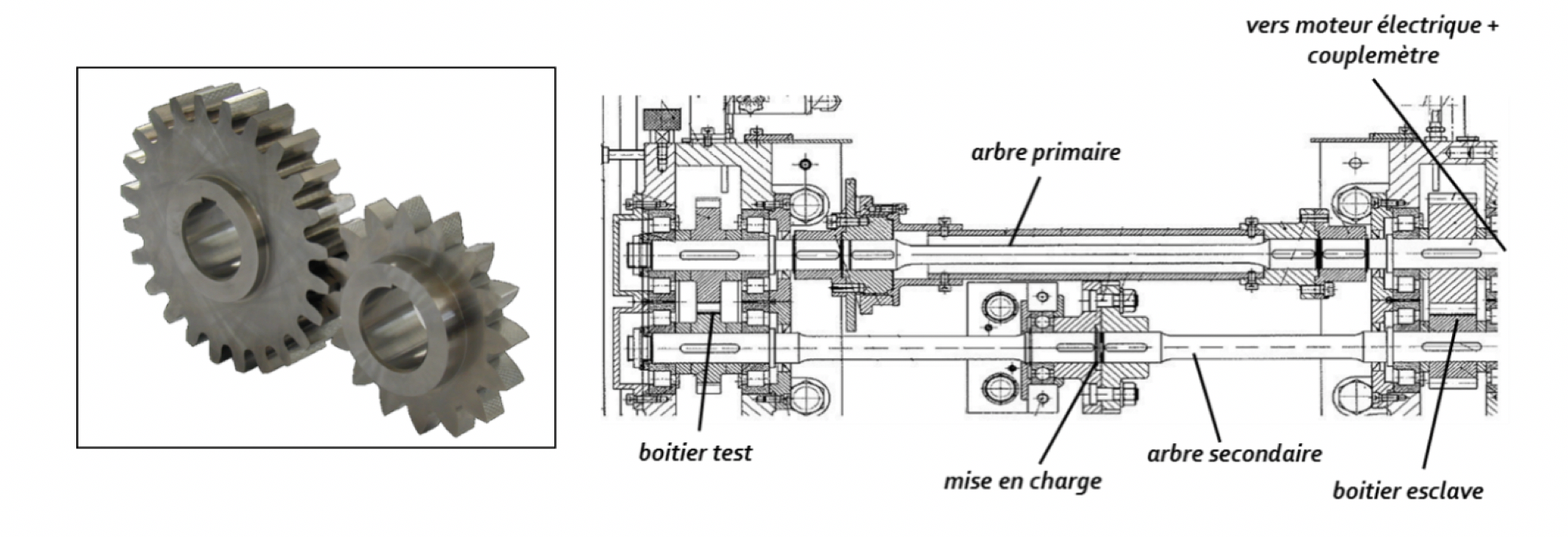

This test bench is developed and marketed by the Technical University of Munich.

This is a closed mechanical loop containing two pairs of gears, one intended for testing (within the test box) and the other for re-driving the primary shaft (slave box).

(within the test gearbox) and the other to drive the primary shaft again (slave gearbox).

By twisting the secondary shaft, high forces can be transmitted within the loop,

while requiring only a small amount of drive power (via an electric motor).

This test bench can be used to assess the resistance of gear teeth to deterioration (running-in, seizing,

adhesive wear, abrasive wear, fatigue due to chipping or micro-chipping) under different conditions

(rotation speed, load) and technical solutions (tooth geometry, material, lubricant, etc.).

The LaMCoS test bench has also been specifically equipped with a torquemeter to measure all the resistive torque in the mechanical loop, and a number of thermocouples to estimate the heat dissipation.

torque of the mechanical loop and numerous thermocouples, making it possible to estimate the heat dissipation

to estimate heat dissipation during the test and thus determine the power losses associated with meshing.

Finally, optical rotary encoders can be installed to measure transmission errors.

Scientific manager : VILLE Fabrice

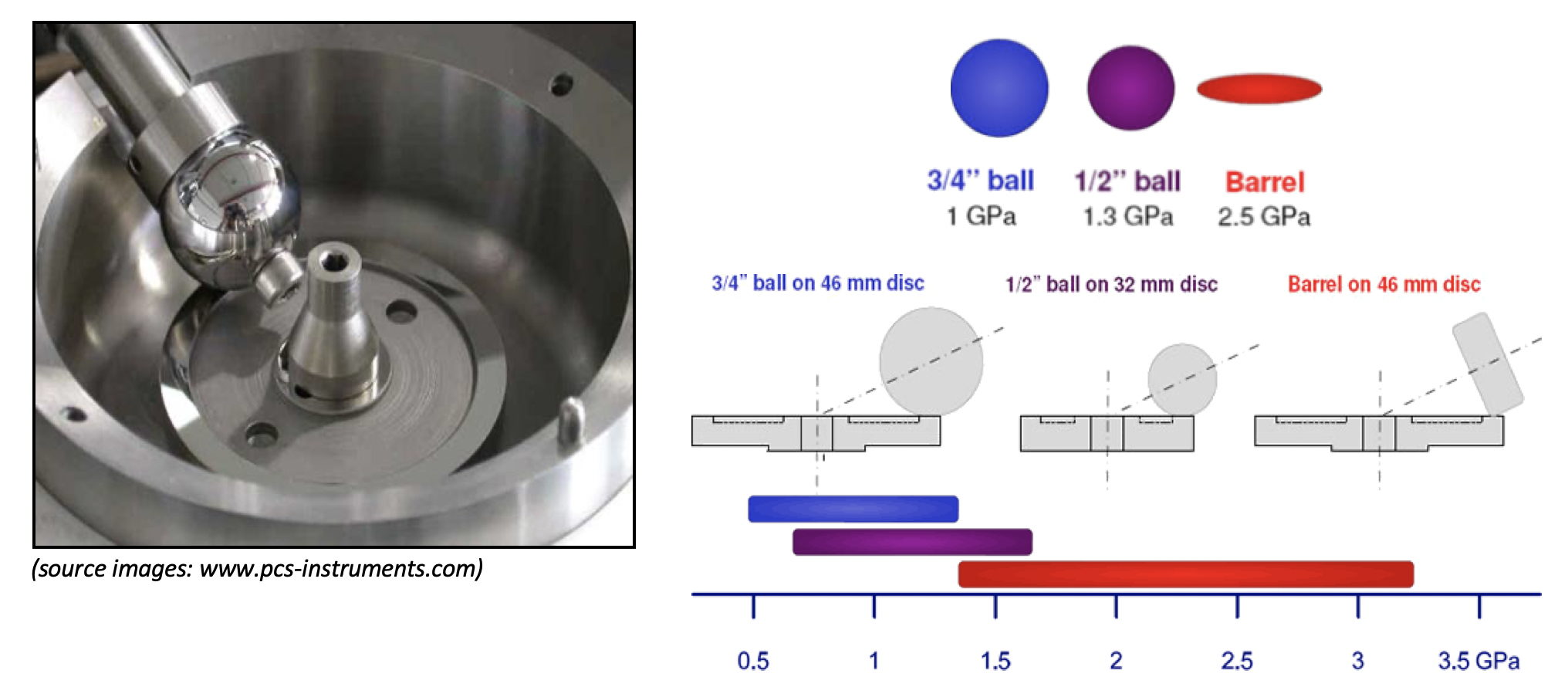

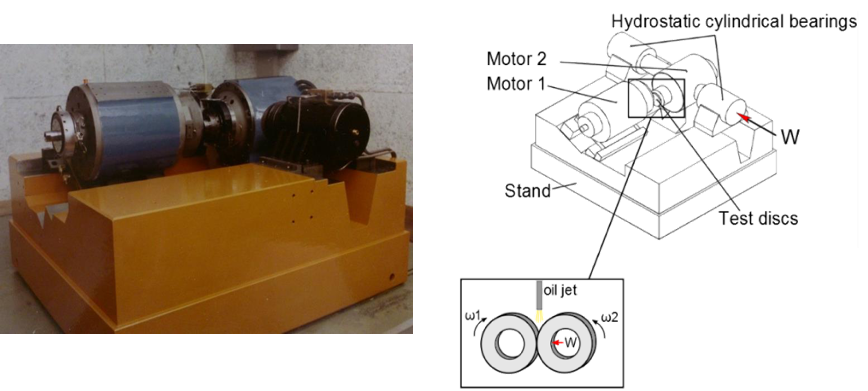

The MBDF machine can be used to simulate all types of ElastoHydroDynamic contact, such as contact between gear teeth, rolling body-ring contact in roller bearings, etc.

gear teeth, rolling body-ring contact in roller bearings, etc.

It is used to assess the influence of contact parameters (kinematics, loads, lubricants, materials, environment, heat, etc.) on induced fatigue,

materials, environment, thermal, etc.) on induced fatigue.

The tests are programmed to stop automatically after a predefined number of cycles or after the appearance of a fault on the surface of the discs detected by the magnetic proximity sensors.

the appearance of a defect on the surface of the discs detected by the magnetic proximity sensors.

The surfaces or metallographic sections of the specimens can be analysed before and after testing

with suitable equipment (microscopy, 3D roughness measurement, etc.).