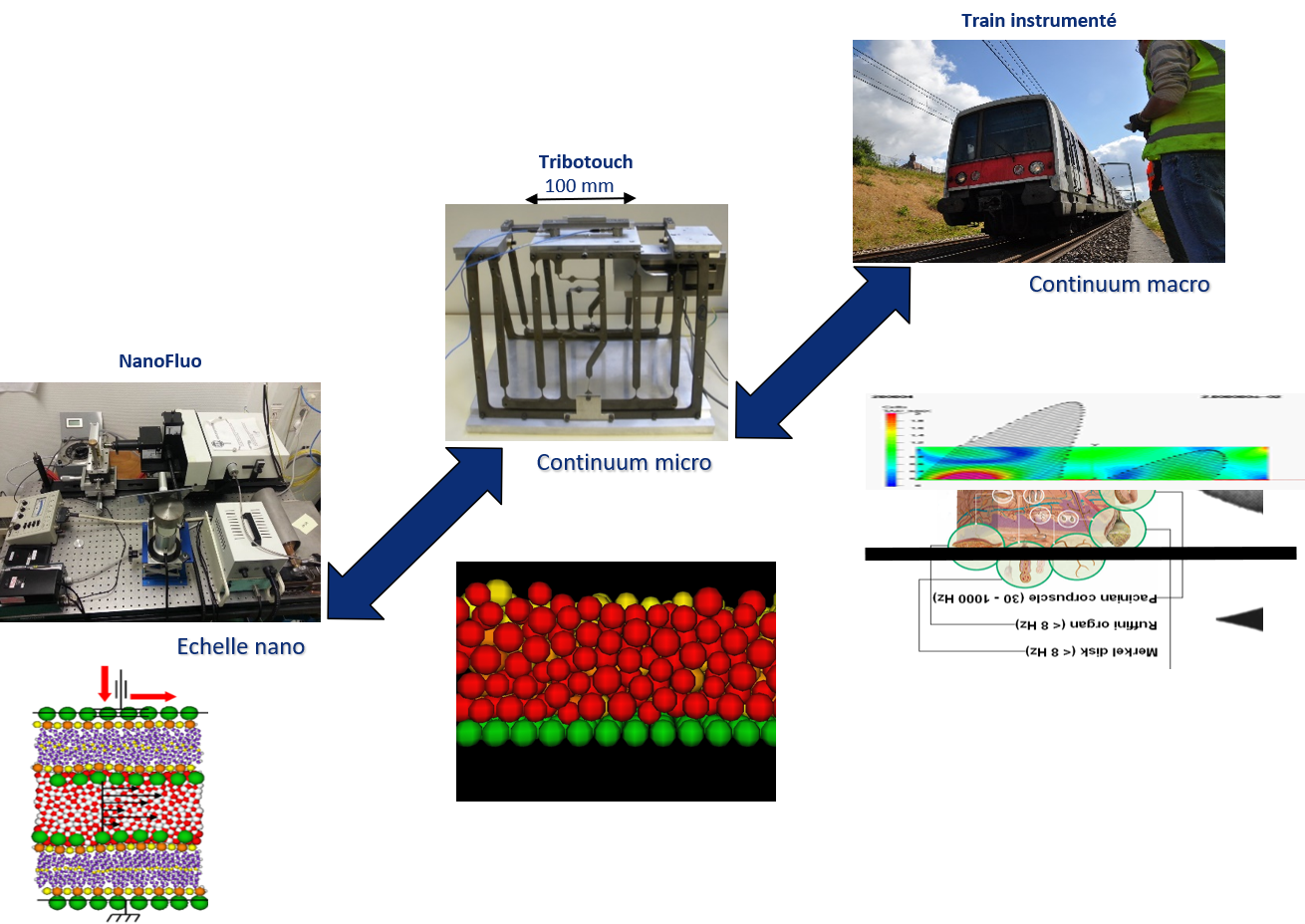

The TMI team focuses on assessing friction and/or wear by monitoring and measuring characteristic quantities locally (fields of speed, pressure, stress, strain, temperature, interface thickness, etc.) inside the contact in by continuing to develop photonic, electronic and acoustic techniques using local probes.

The TMI team therefore has experimental facilities covering a wide range of scales, speeds, forces and temperatures.

Experimental observations are constantly coupled with theoretical and numerical developments. From a theoretical and numerical point of view, tribo-mechanical-fidelic models are developed, translating the local and global behaviour of the contact and reflecting the rheology of the separating medium and its interaction with the surfaces.

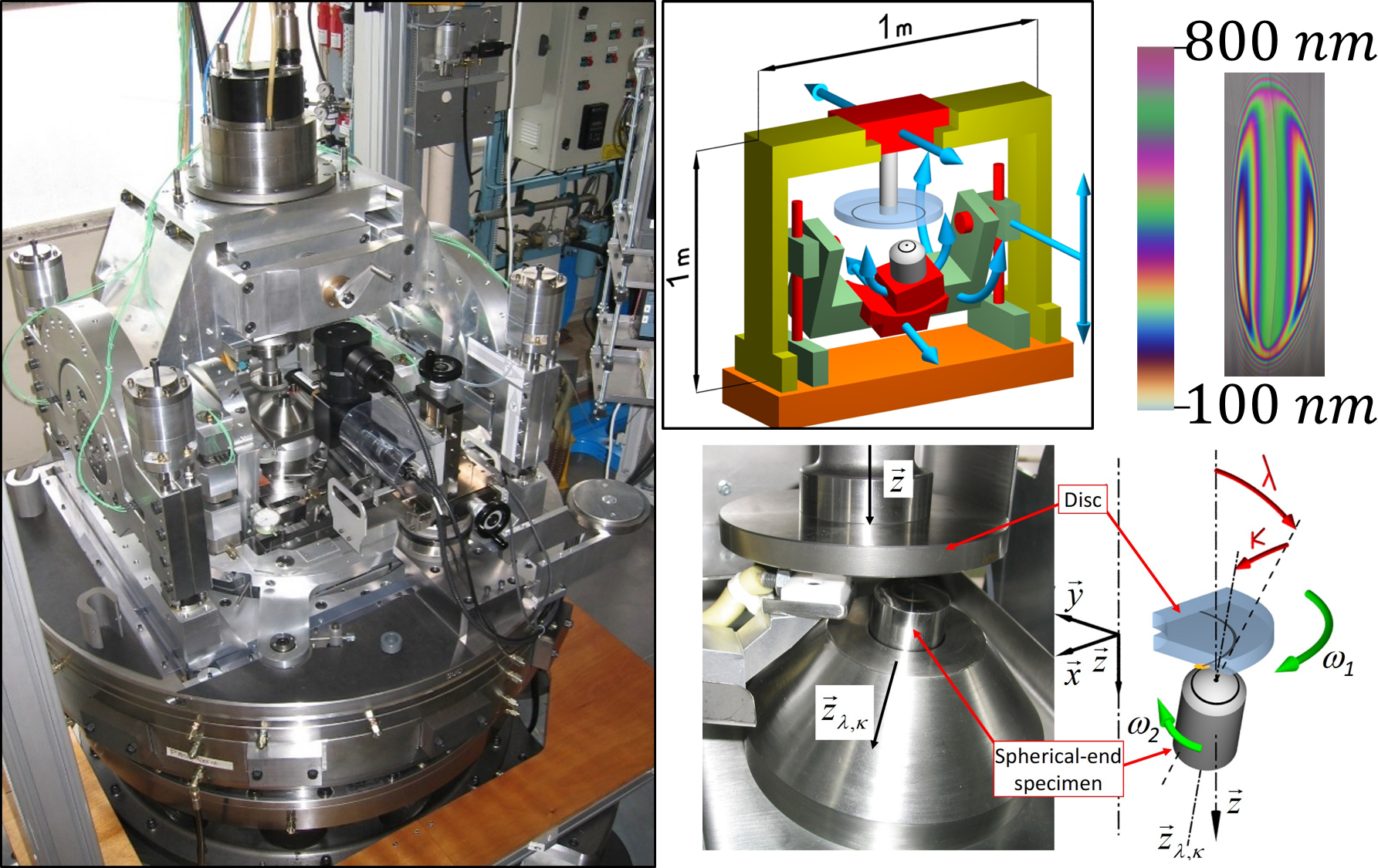

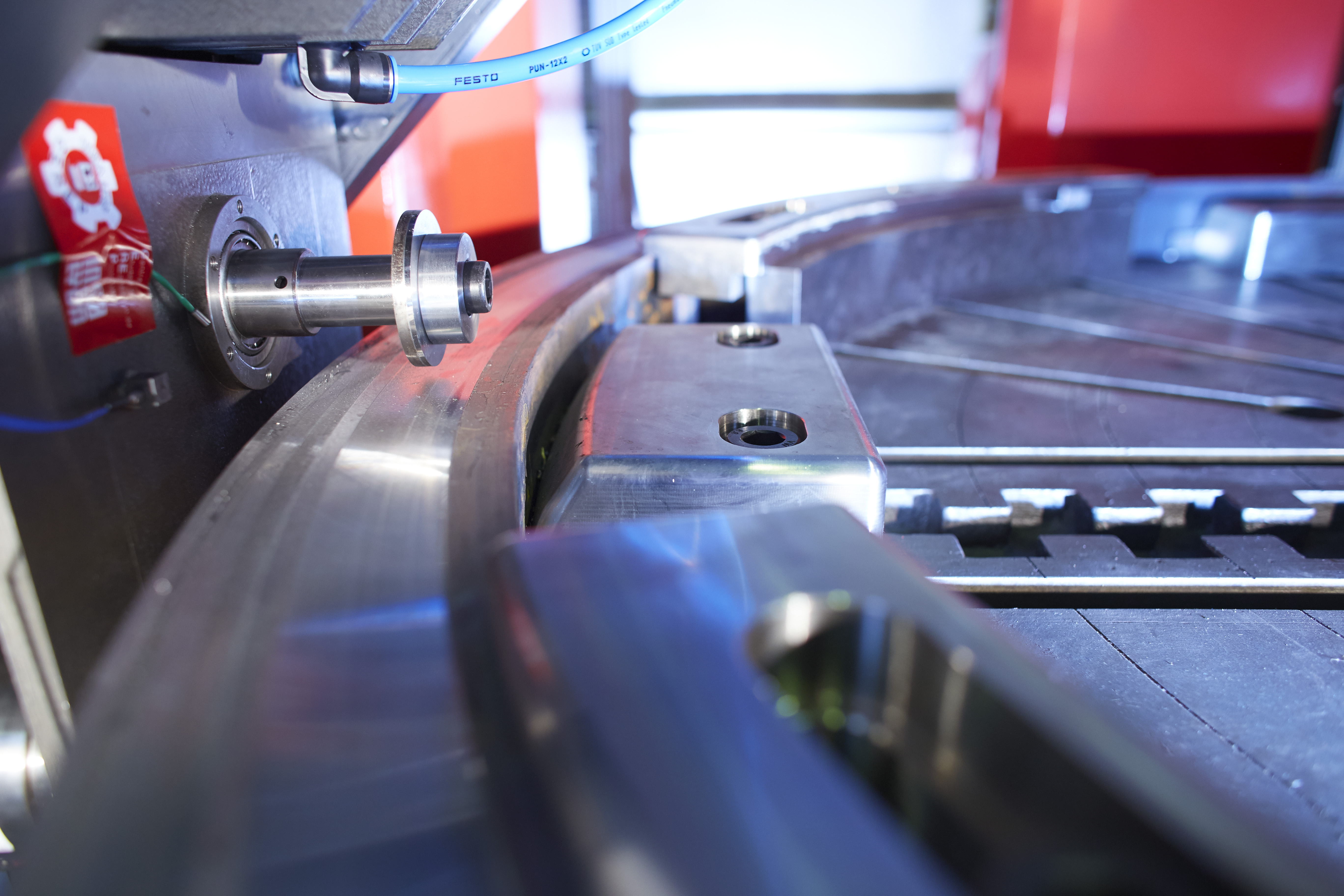

Tribogyr

The Tribogyr experimental bench is a tribometer for the full-scale study of lubricated or non-lubricated contacts with complex geometry and kinematics. It can be used to in particular to simulate, on a 1:1 scale, the collar-roller contact in large bearings. :

Normal force: 10 to 3000N

Linear speed: 0.2 to 30 m/s (22,000 rpm)

Imposed sliding, pivoting and skewing

Contact pressure: 0.1 to 4 GPa

Power dissipated in the contact: 1 W to 10 kW

The associated instrumentation enables friction to be measured (XYZ forces and moments on the two crews) as well as the thickness of the of the lubricant film in the contact (white light interferometry).

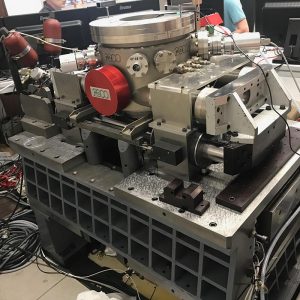

Triboring

Triboring is an original large-scale roller-ring tribometer with controlled sliding that can simultaneously reproduce two different contact conditions. Particularly suited to the study of wear and fatigue of rolling contacts, this tribometer was initially developed to reproduce wheel-rail contact on a scale of contact at 1/10th scale in partnership with the RATP.

Credits I@L/PHOTOS Alexis Chézière

Pedeba

The Pedeba test bench is a high-rigidity friction simulator for studying friction in servo-controlled reciprocating motion displacement with various kinematics options. Vertical servo-control in force or displacement.

Load: 50 to 1500N

Frequency: 0.01mHz to 150Hz

Offset: ± 2µm to ± 50mm

Temperature : -160 to 120°C

Contact geometry: plane/plane, sphere/plane, pebble/plane, specific assemblies

Three-dimensional measurement of force and variations in contact thickness during rolling and sliding. Visualisation of the contact by conventional camera (x 700) or high-speed camera

Controlled environment: vacuum chamber (up to 10-7 Pa), cryogenic chamber in dry atmosphere (from 20 to -160°C).

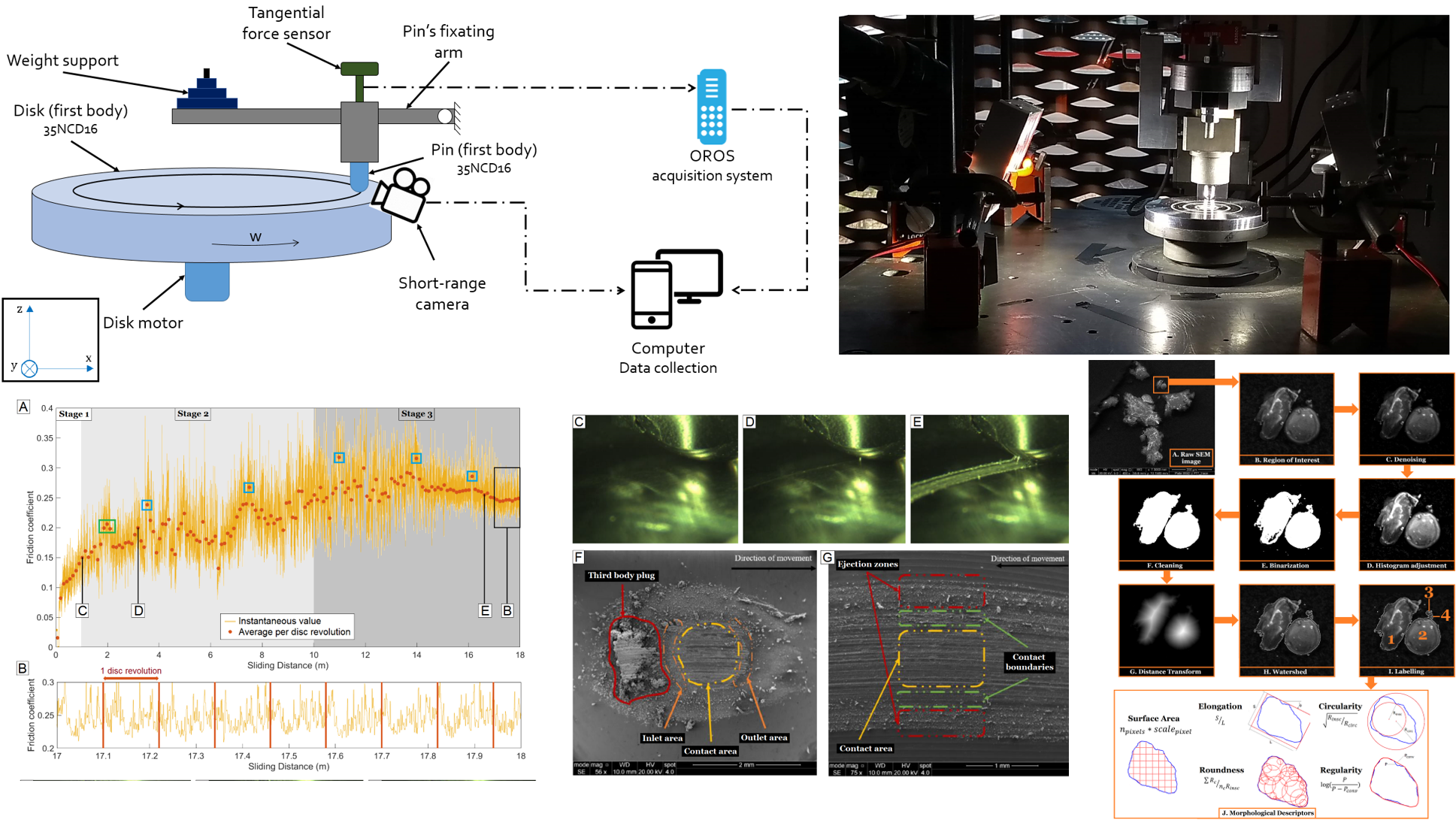

Morphoréo

The objective of the MorphoRheo experimental set-up is to construct logical relationships between the observed morphology of a contact interface and the rheology of the solid flows that take place there. It consists of a pion-disc tribometer equipped with measurement and observation equipment (gauges, sensors, accelerometers, high-speed cameras), and an environmental chamber to control the experiment's gaseous atmosphere. These experimental resources are coupled with a digital processing chain based on multimode microscopic observation (optical, electronic, EDX, etc.), morphological characterisation algorithms for the particles and textures observed in the contact, and supervised machine learning approaches that enable all these observables to be linked in a repeatable manner.

The team has a wide range of other equipment for tribometry, rheological characterisation and microscopy, spectroscopy : see list